I’ve often considered making nicer projects in the wood shop, but up till now, I’ve pretty much limited myself to camping equipment.

Mostly it’s been fear that I can’t make something perfect. Add in the fact that I’m good at sourcing things that are pretty close to what I really want and then modifying them.

And it really kills me when people ask me if I built the cabinets in the dining room.

But it’s been itching at me. I keep kicking around ideas for custom cases for some older tools that don’t have them. And I keep coming up with excuses why I can’t do it.

But last week I noticed this.

I plucked this tool stand out of the trash. I think my drill press is a bit too much for it.

It’s been bugging me for years that all my tools are on random stands, so now it’s time to bite the bullet and make some sawdust.

So I watched this Video about building cabinets with pocket screws and decided to give it a shot.

I spent some time sketching & planning & drawing.

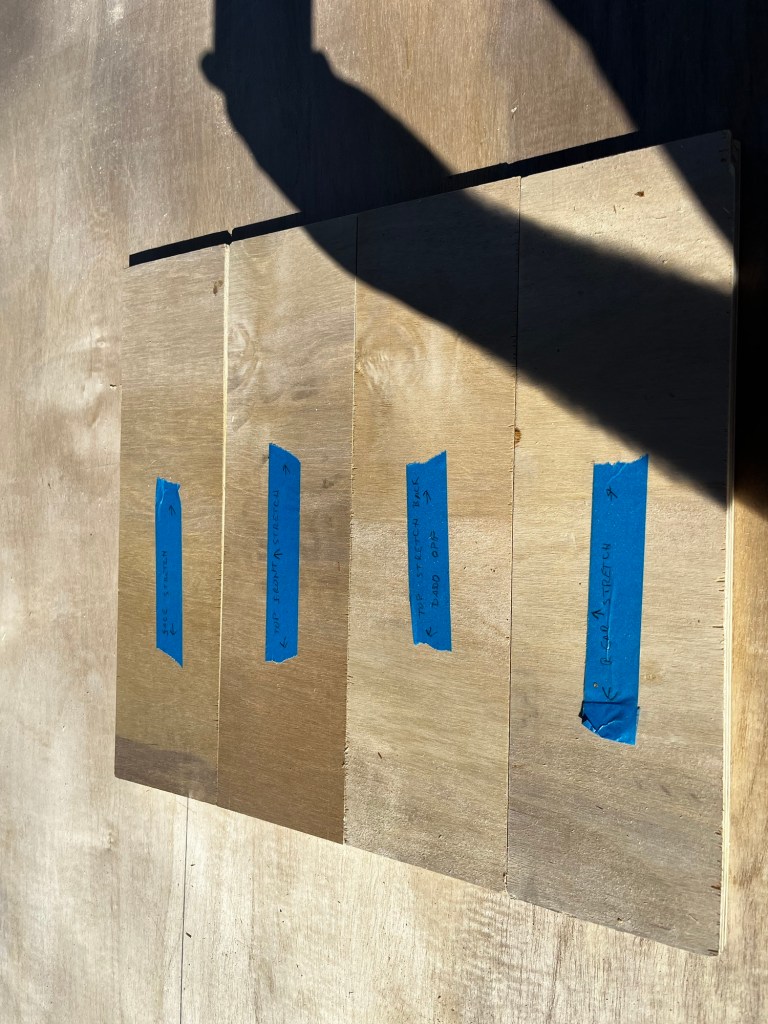

The cabinet went together quickly and easily. I used a circular saw to cut the sheet of plywood in half, then cut all the individual pieces out on the table saw.

A drill & the pocket hole jig was used to make all the holes, and the installation driver for assembly.

I’m really happy to report that I can build perfectly serviceable cabinets without a $100,000 wood shop. Or even $1,000 wood shop. This cabinet isn’t nice enough for the kitchen, but it’s just fine for the shop. I think after I build a few more for the shop, I will be able to make some nice enough for the civilized parts of the house.

I took the opportunity with my new base to address a safety concern with my drill – the power switch is on the motor housing. In the back. Out of sight. Where you’ll never find it when you really need it in a hurry. Jokes on me though – the power cord is too short, so I’m going to have to rewire the motor.

So, I need a cabinet that’s no more than 20 inches tall so I can fit the drill press under the camping equipment loft. Twenty four inches deep will accommodate all of my tools, and it’s the depth of a standard kitchen lower cabinet. Someday it will be nice to line a few of these up together.

I added these collapsible casters so I can roll it around, but drop the press onto a solid footing when it’s time to work.

The drawer was a last minute add. I was originally going to use my traditional milk crate, but that would have resulted in a lot of wasted space and been useless for small bits.

The band saw is getting a new base next. Same casters & safety switch.