Because you know I can’t do a project without things going sideways.

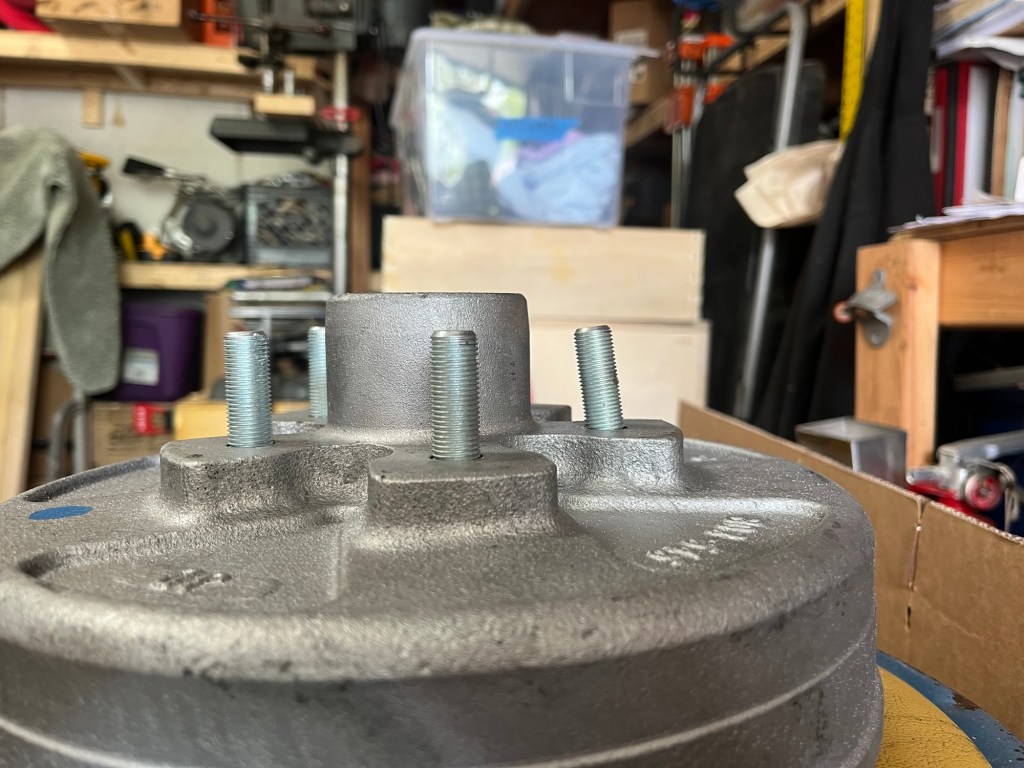

I decided to dry fit my wheels on the hubs before hanging the hubs on the trailer and……

…..erupted in a cloud of profanity so robust that Old Man Parker* would have been impressed.

One of the studs was bent. There’s no way to get a wheel on this hub, and I’m not good enough at loading to balance the trailer on one wheel. I’ve got to get this trailer on the road in five damn days.

So I got on the phone with eTrailer on a Sunday afternoon to see if they could overnight me a new hub.

Instead of a new hub, they offered me a new stud. And I learned that studs can be removed from hubs. All it takes is a BFH.

So I knocked the stud out with my favorite 3 pound hammer and confirmed the measurements. I was told the replacement stud would be shipped out on Monday morning.

But wait, I’ve got ten perfectly useable studs on the old hubs. Maybe I won’t have to wait for a new stud to get delivered.

Instead of driving a stud out with a hammer and potentially damaging the threads, I decide to press it out with a giant C-clamp and a socket. (The socket is placed behind the stud to give the backend a place to go when the clamp pushes on the front.)

And it came out like butter. 👍🏼

And it was totally the wrong size. The shoulder was thicker & longer. 👎🏼

Looks like I’ll have to wait on the replacement getting delivered.

Monday morning, my studs (two actually) shipped, but according to the tracking info, they wouldn’t arrive until Thursday afternoon. So, onto plan C. {Plan C seems to be the theme recently, doesn’t it. I may have to explore that.}

If studs are replaceable, it’s pretty likely that some store stocks them, so let’s travel back in time to a world without the internet.

There’s an auto parts store within walking distance from my house so I head over there with the bent stud. I should have known things weren’t going to go well when the counter man asked me for the make & model of the car.

I responded, “It’s for a utility trailer, but we can’t even look up the trailer, because I’m adding brakes to a trailer that never had them.”

There’s a subreddit called r/WatchPeopleDieInside, and that’s exactly what I did. His brain did a hard reboot and he came back fighting, so I’ll give him credit for that.

He went digging through the bins in the back and came back with two studs, neither of which would fit.

The NAPA in the next town (a ten minute drive) came through, but only sold the studs in a five pack. Four extras that I hope to never need.

So now to get the new stud in.

I consider my BFH, but I don’t want to ding up the beautiful machining on the inside of the brake drum. [In all seriousness, imperfections on the drum will shorten the life of the brakes.]

Back to the C-clamp & socket method. This time the socket goes in front of the stud. I struggle with this for a while, trying to find a way to hold the drum steady, stud through the hole, hold the clamp & socket & tighten the clamp. By my count I’m about four hands short of what I need.

I can pull the stud in with a nut. They actually make a tool for this, it’s puts a bearing between the nut & the drum so the lug nut can rotate freely. But a couple of washers with a dab of grease between will give me the same effect for zero dollars.

Hand thread the nut down & feel the knurling engage. Start to tighten with the ratchet. I see the stud start seating. As the stud seats deeper, it’s requiring more torque, and more torque. And I can’t hold the drum still anymore, but the base of the stud still needs to get pulled in deeper.

I wonder if there’s a good way to add friction to this steel drum, without adding a load that could bend it out of true?

What do you know. Rubber has a higher coefficient of friction that steel. And a larger diameter circle exerts less torque at the perimeter. And the drum is designed to take loads at the studs.

Replacing the ratchet handle with my breaker bar and the stud was so easy to pull in fully.

One of my coworkers recommended that I upgrade the hubs to “Bearing Buddy” units. These are aimed primarily at boat trailer applications but seemed like a worthwhile upgrade.

They add a zerk to the spindle end so you can add grease without disassembling the entire axle.

*Ralphie Parker is the narrator of A Christmas Story. His father is never named, but only called “the Old Man”.