So I wanted to be able to safely drill into the end of a piece of round stock, but couldn’t figure out a decent way to hold my work that kept my fingers away from sharp steel bits spinning at high speeds.

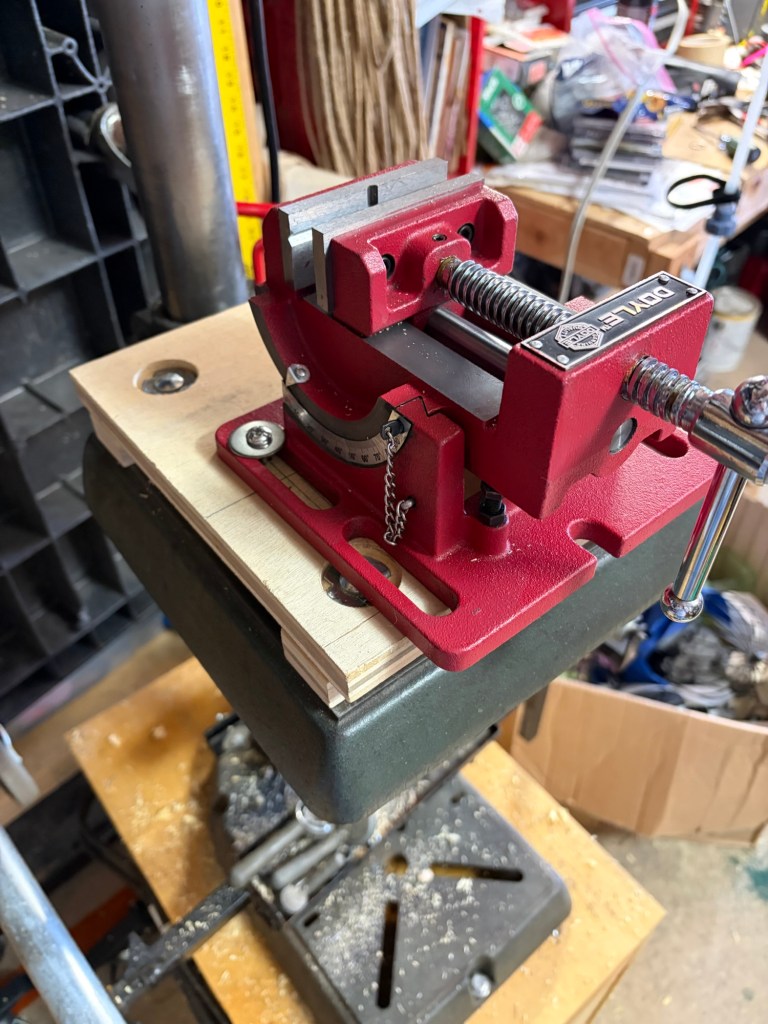

Then I went to Harbor Freight and found this cradle vice.

But now I need to be able to secure the vice to the drill press table and the hole on the vice don’t line up with the holes on the table at all.

AT ALL!

A piece of 3/4 plywood will allow me to put holes anywhere I want to, so I grab a a scrap and cut it to match the table.

I added a pair of runners under the plywood so the vice mounting hardware won’t damage my cast iron table.

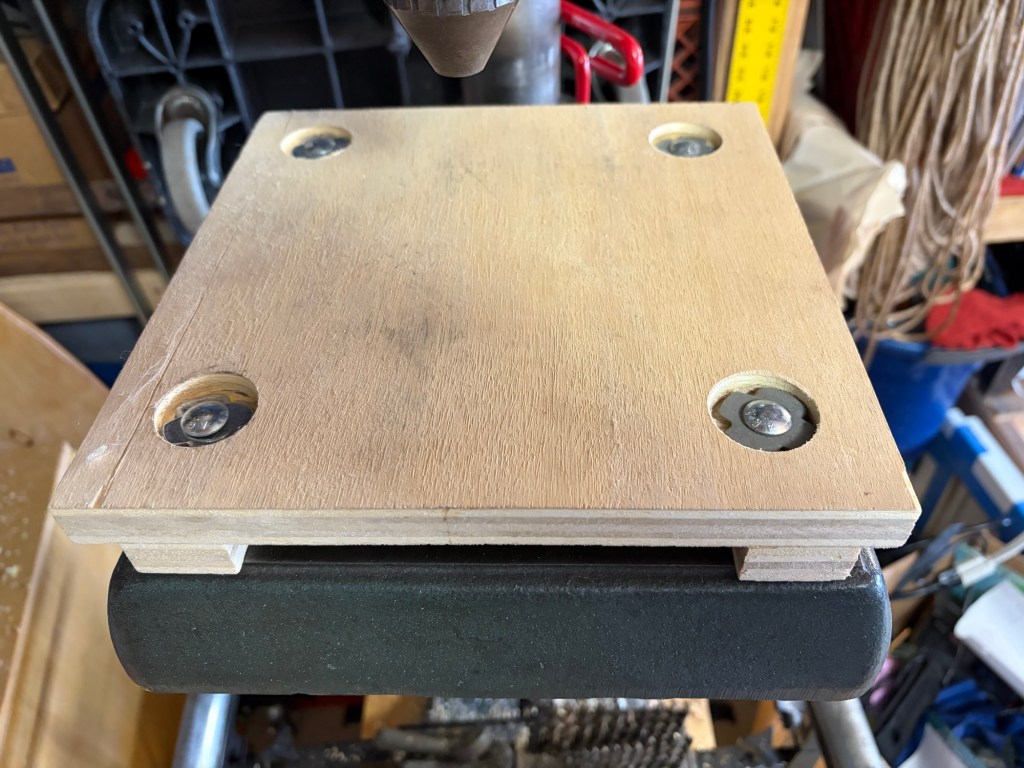

The wooden base is bolted to the table with carriage bolts / torque washers above and fender washer / wing nut below.

I used a Forstner bit to get the carriage bolt heads below the wooden deck so the vice can slide fore and aft as needed.

The vice is secured to the wooden deck with Tee nuts under the plywood and screws / washers above the vice. With these two screws I have enough fore & aft movement to center anything that the jaws can accommodate.

This vice tilts front to back and the drill press table tilts left to right, so I can now drill at any angle I desire.

The wood for this project came from my scrap bin and the hardware was in my on-hand stash, so I spent zero dollars building this.