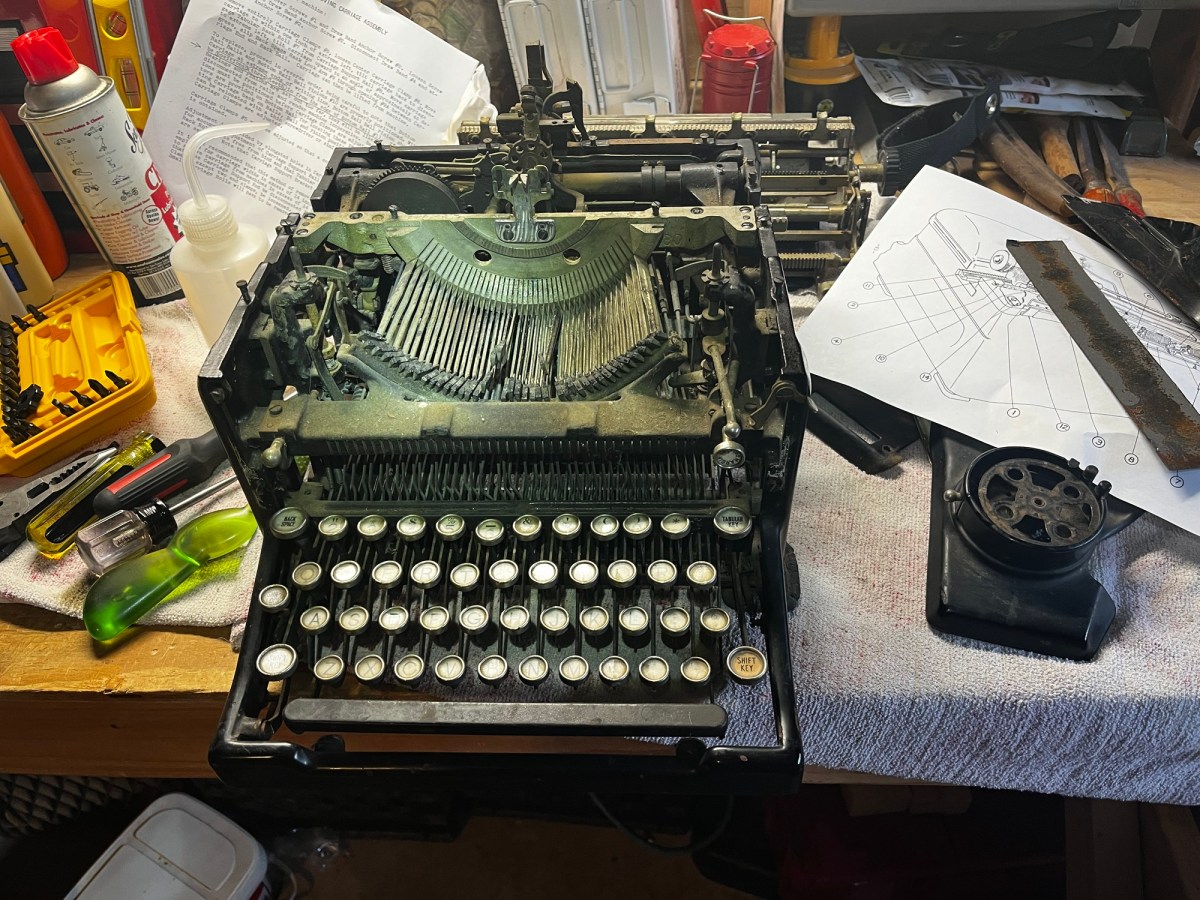

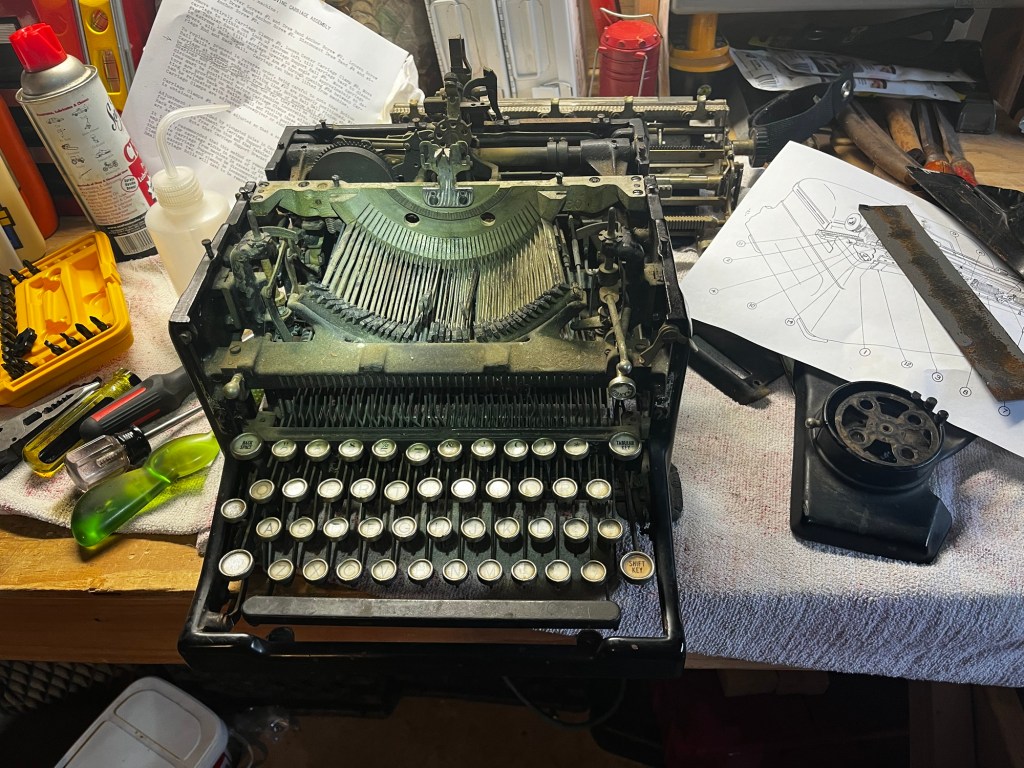

[Apologies, dear reader. No pictures on this post. I got into the zone while working & never stopped to take photos.]

Actually, it’s not as bad as all that. Just a lot of information that needs to be made visible on the ceiling so you can install things aligned with the window. You’re going to need to mark the window frame, ceiling joists, and mounting hardware locations on the ceiling.

Step one (skip if you plan to paint the ceiling.) Painter’s tape gives you a place to make marks without marring the ceiling. Go big here. A few inches past the outside of the window trim. A few inches further out than you think you’ll need.

Step 2 (get creative). You need to transfer the outside, and maybe the center, of your window from the wall to the ceiling. I used a combination square and a speed square.

The blade of the combination square goes against the window trim. But 50 years of paint & caulk have built up the side of the trim so it’s no longer square to the wall. I used the speed square against the wall to rotate the head of the combination square. Then I traced the speed square along the ceiling.

If you’re paying attention, you know that because the head of the combo square is thicker than the blade, my line is about 3/8” inboard of the window trim. Given that it’s the same on each side of the window, it doesn’t matter.

For the center line, I eyeballed my blade on the center divider of the window and traced both left and right sides of the head. Then I drew a center line between those two marks. (It’s easier to eyeball the middle of a 3/4” gap than the middle of a 72” span).

Step 3 (Finally something straightforward). Use your stud finder to locate the ceiling joists and mark them on your tape.

Step 4 (in which something that your partner will recognize as progress actually happens) Now that you know where the window treatment has to be and where the joists are, you can hold your window treatment against the ceiling and plan your fasteners. Can you lag it into joists? Are you using toggle bolts?

Mark your ceiling where the fasteners are going.

Step 5 (making holes, finally). Drill your pilot holes. The sizes you need are determined by your fasteners.

Step 6 (no subtitle needed) Peel off your painter’s tape or paint the ceiling after your holes are drilled.

Step 7 (The light at the end of the tunnel. Or is that an oncoming train?) Attach your mounting hardware to the ceiling and your window treatment to the mounting hardware.