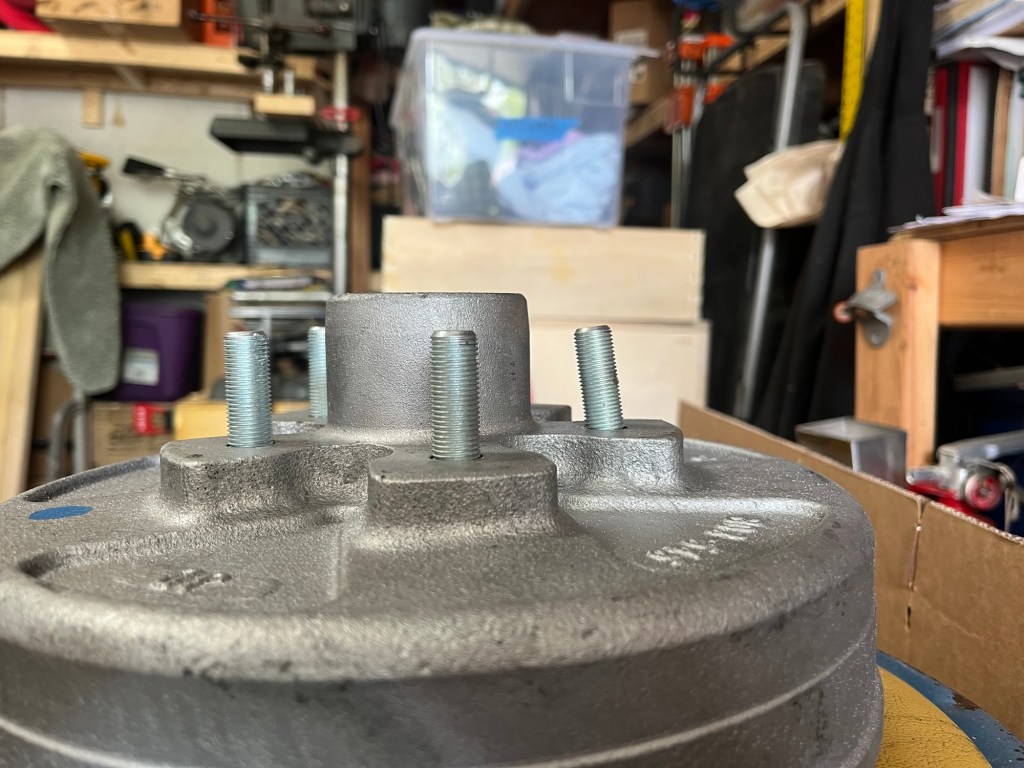

So I wanted to be able to safely drill into the end of a piece of round stock, but couldn’t figure out a decent way to hold my work that kept my fingers away from sharp steel bits spinning at high speeds.

Then I went to Harbor Freight and found this cradle vice.

But now I need to be able to secure the vice to the drill press table and the hole on the vice don’t line up with the holes on the table at all.

AT ALL!

A piece of 3/4 plywood will allow me to put holes anywhere I want to, so I grab a a scrap and cut it to match the table.

Continue reading “Adding cradle vise to the drill press”