When I bought the bandsaw a few years ago, it was on this angle iron base. Perfectly functional, and purely functional. It works, but it looks like a bunch of angle iron off cuts (which is what it is).

Once I built the base for the drill press, I decided that the band saw needed a matching base.

Let’s take a little tour of my mental processes when designing a project like this.

Of course the second cabinet is going to be a bit nicer than the first. And the bandsaw is going to require a bit more engineering than the drill press did.

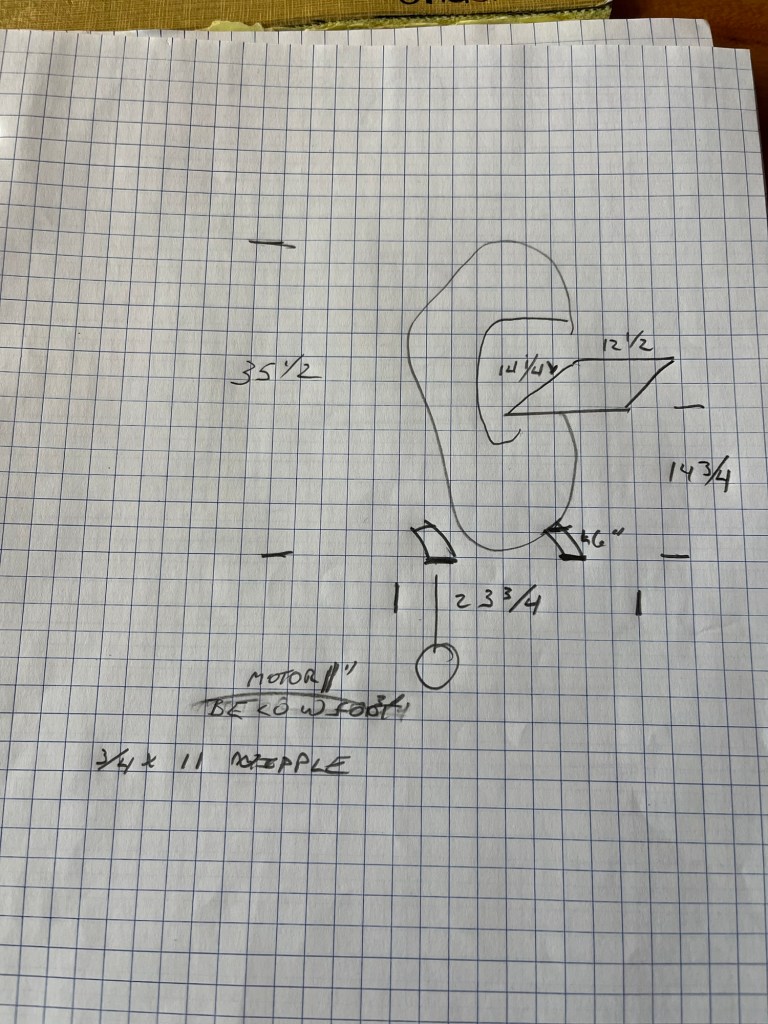

First off, the band saw motor hangs below the saw itself, where the drill press motor is attached to the head.

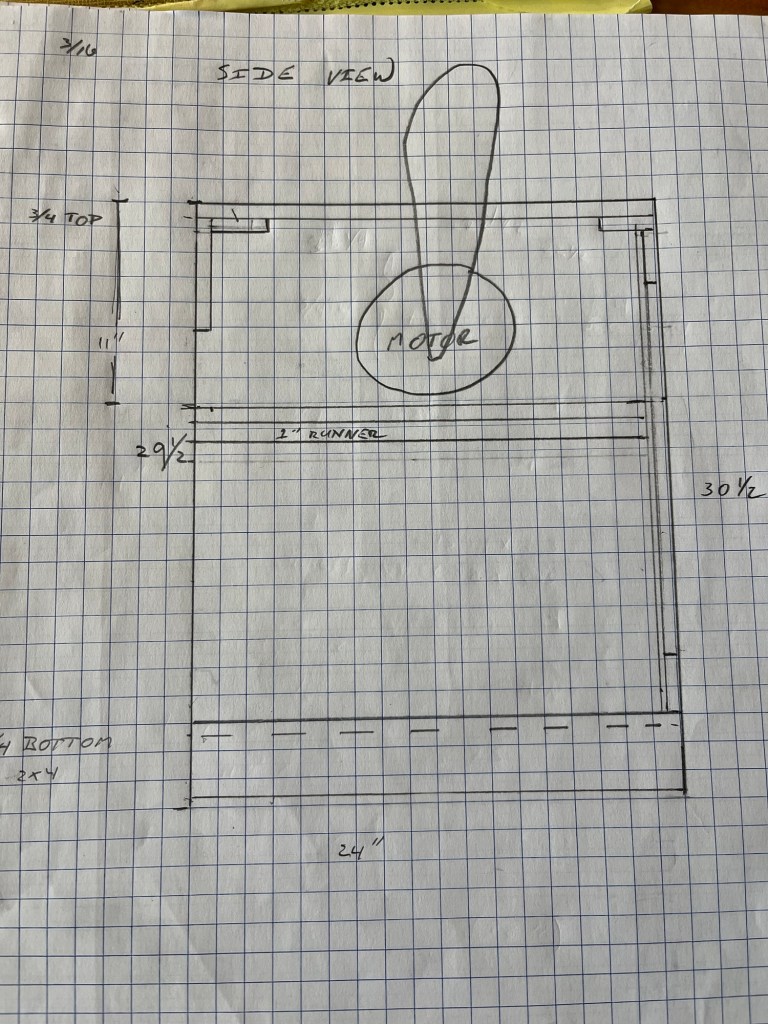

So I need a fixed shelf below the motor. It’s 10 inches from the saw deck to the motor deck.

And I’m going to need a hole through the saw deck for the belt to pass through. Speaking of the belt, I’d like to have a belt guard for safety.

Speaking of safety, I’m going to incorporate a modern power tool paddle switch again.

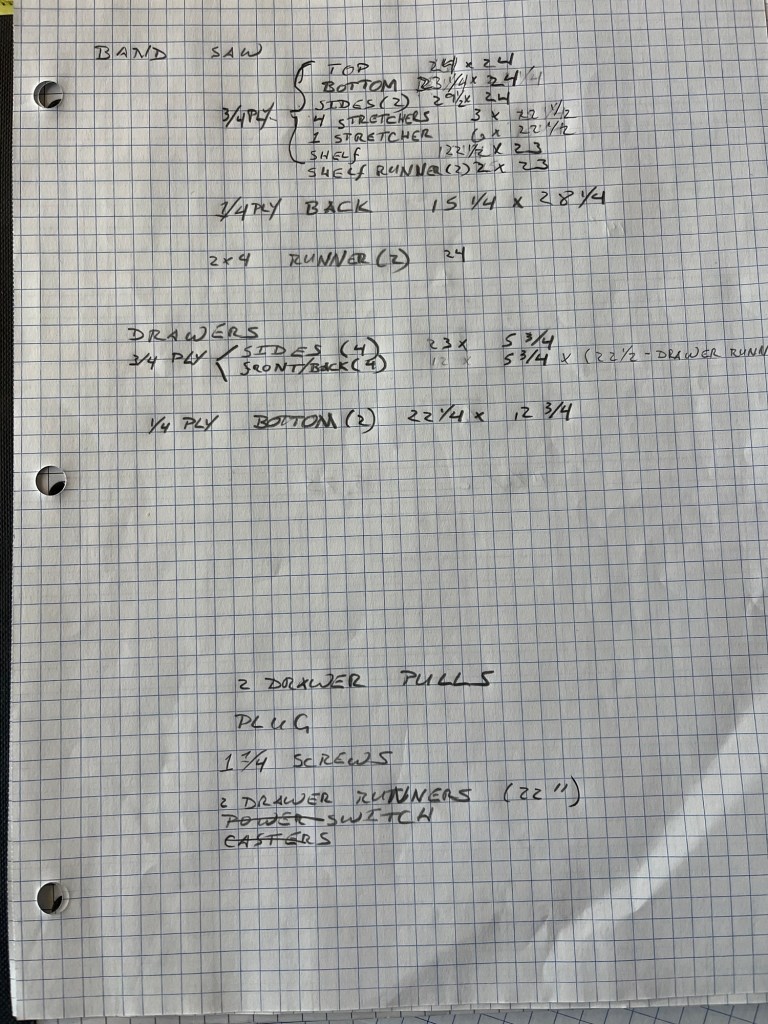

On the drill press base, I had one deep drawer. I want to have two shallower drawers on this one. It’s too easy to loose things in the deep drawer.

I’d also like to improve the joinery on the drawers. The drawer on the drill press was an afterthought- it was originally going to be a milk crate.

And a work light would be nice, if I can find one. The grinder has a light attached and it makes work so much easier when there’s plenty of light.

I’m going to stick with the flip up casters for mobility and the 2×4 rails when it’s parked. I feel like this solution is more stable when parked than “locking” casters.

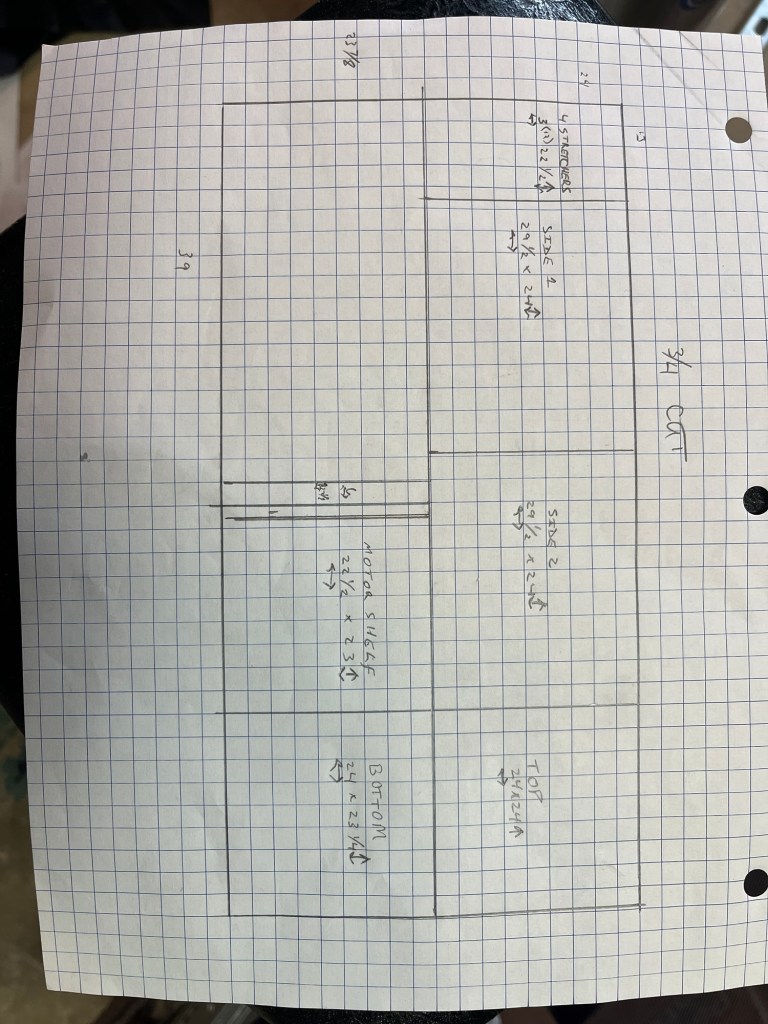

So, I take all these ideas and sketch them out. Then turn the sketches into a set of measured drawings.

The measured drawings become a parts list and cut sheet.

Then, in a flurry of sawdust & curses, it becomes a base cabinet for the bandsaw.